Ceramic Cork Drum for Hauni Protos Cigatette Machine Shear Cut Drum

Shear cut cork drums have been used on Hauni Protos tobacco machines which came into the market later than Protos 80. Traditional shear cut cork drums of Hauni Protos tobacco machines( traditional drum for short) have knives combined with suction plates. In the production process, you need to dismantle the whole drum when the cutting edge breaks or turns blunt and the cutting can not be carried out smoothly or continuously. The drum need to be returned to the manufacturer for repair or just to be thrown away. Normally, the working life of this kind of traditional drum is just around 4,500 hours.

Our innovated shear cut cork drums (innovated drum for short) that we developed for Hauni Protos cigarette machines not only have improvement regarding structure, but also have creations about material.

|

|

Traditional Shear Cut Cork Drum

|

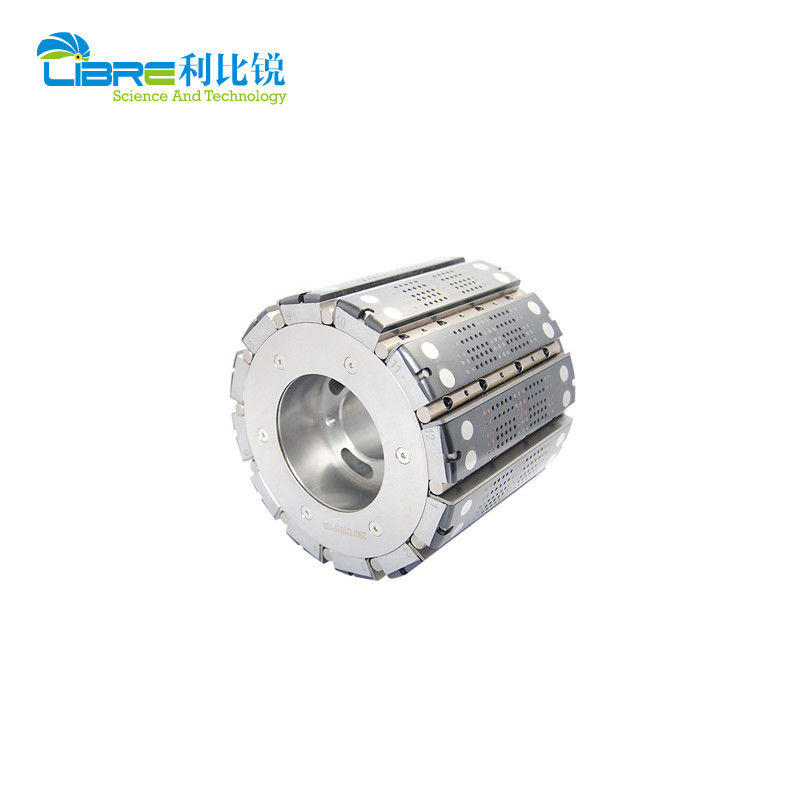

Our Innovated Shear Cut Cork Drum with Steel Body

|

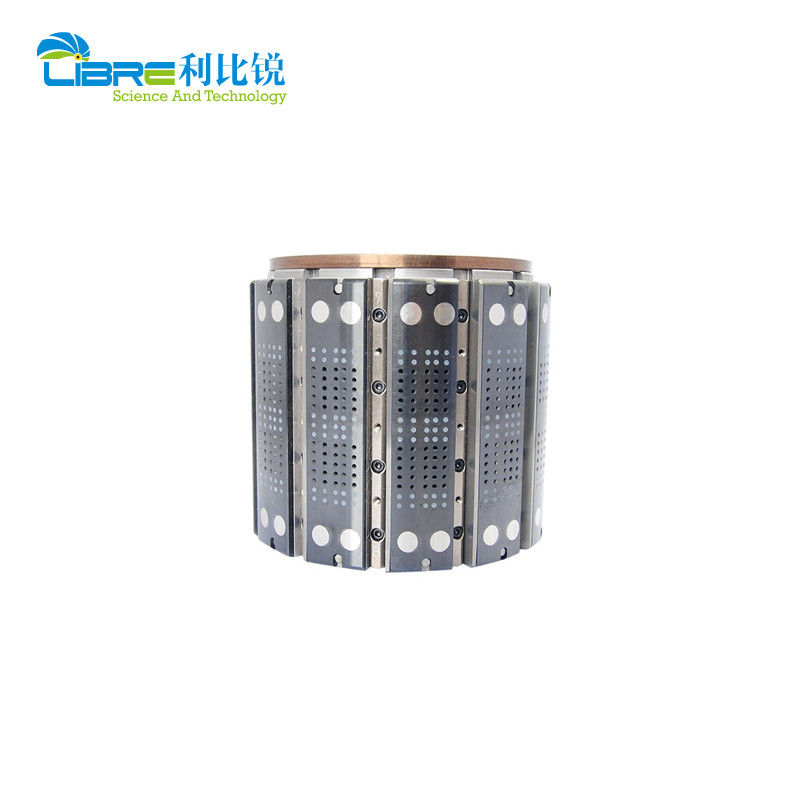

Our Innovated Shear Cut Cork Drum with Aluminum Body

|

|

Knife and Suction Plate Relationship

|

Combined together

|

Separate from each other

|

Separate from each other

|

|

Weight

|

11KG

|

9.5KG

|

6.5KG

|

|

Material

|

Carbide plates + steel body

|

Ceramic plates + steel body

|

Ceramic plates + aluminum body

|

|

Lifetime

|

180~360 days

|

900~1000 days

|

1000~1200 days

|

In structure, the knives and suction plates were separated on our innovated drums. The changed design makes the suction plate work under a sole purpose of sucking up tipping papers, and be no longer easy to break. Being separated from suction plates, the knives now have 4 reversible cutting edges can be used as four brand new knives by turning one side up after another when the working side gets blunt or breaks. So reversible cutting knife has a working life four times longer(as long as approx. 18,000 hours) than the normal one-edge knife which was combined with suction plates on traditional drums. And as a result, the spare part cost is reduced and replacement and maintenance requirement is no longer frequently needed.

Different from traditional drum, our innovative drum can offer you different choice of drum body material. You can choose steel body or aluminum body. Aluminum body helps reduce overall weight of the drum. In addition to that, the suction plate is made of composite ceramic material, which also largely reduces the weight of the drum. The weight of our steel body ceramic drum is just 9.5KG, and the weight of our aluminum body ceramic drum is just 6.5KG, which is obviously lighter than traditional drum. The reduced weight effectively lightens the load on the gear system and prolong the working life of it, thus the gear system can work precisely. And the ceramic material has better performance in wear resistance, anti-erosion, easy-cleaning than carbide material, so our innovated ceramic shear cut cork drum can improve working efficiency, reduce costs and simplify maintenance requirements.

Improvements of Our Innovated Drum Compared With Traditional Drum:

- Knives Separated from Suction Plates

Knives are separated from suction plates, so that knives can be replaced easily in case of bluntness or breakage and the use of suction plates won’t be affected.

The knife have four cutting edges, which can be used one after another by flipping over from the used side to a new side.

Suction plates are mad from technical ceramic, which increases working life and at the same time decreases overall weight of the drum.

Aluminum body are available for your choice. It helps further reduces drum weight, and decreases pressure on gearing system.

Other More Spare Parts:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!