Dubai International Tobacco Exhibition

On November 11, 2025, Chengdu Libre Technology Co., Ltd. once again joined hands with a large number of global customers to make an appearance at the Dubai International Tobacco Exhibition. During the two-day exhibition, we not only had a warm reunion with old partners but also established sincere connections with new clients. Relying on high-quality products and professional services, we gained wide recognition and deep trust from customers at home and abroad.

At the exhibition site, core long-term cooperative customers such as PIM and JTI made a special trip to attend. They not only highly affirmed the stable quality of the company's existing products but also clearly expressed their willingness to deepen future cooperation. Customers advised us to always put product quality at the core, continuously promote product iteration and innovation, integrate high-quality resources in the industrial chain, and strive to build a one-stop procurement solution to help customers reduce procurement costs and communication inefficiencies and achieve mutual benefit and win-win results.

In front of the popular exhibition booth, a variety of core products became the focus of customers' eager consultation. Samples such as Garniture tapes, Cigarette Filter Rod Cut Off Knives , and Carbide Circular Knife with the service advantages of "in-stock supply and immediate response", perfectly met customers' procurement needs for urgent products. Their excellent cost-effectiveness and stable quality have long accumulated a good reputation in the industry.

It is worth mentioning that the company's cigarette testing equipment became the "star product" of this exhibition. Cigarette bead bursting testing equipment and cigar testing equipment successfully attracted many new and old customers to stop and observe as well as conduct in-depth discussions, thanks to their accurate testing technology and intelligent operation experience, becoming a major highlight at the exhibition site.

This trip to Dubai was not only a display of the company's brand strength but also an opportunity to deepen cooperation and expand the market. Looking forward to 2026, Chengdu Libre Technology will go to Dortmund as promised. At that time, we will bring a more abundant product system, a wider range of service scenarios, and more complete accessory solutions to accurately meet the increasingly diversified needs of global customers. We will work hand in hand with partners at home and abroad to write a new chapter in the development of the industry!

Libre will attend WT Middle East Dubai 2025

WT Middle East Dubai

11. - 12. November 2025 | Exhibition and Conference of the tobacco industry

We LIBRE SCIENCE AND TECHNOLOGY CO.,LTD will attend World Tobacco Middle East in Dubai, 2025.

The "World Tobacco Middle East" (WT Middle East), a prominent trade fair for the tobacco industry, is held annually at the Dubai World Trade Center (DWTC). Since its inception in 1979, it has established itself as a central meeting point for the industry.

Organized by Quartz Business Media Ltd., the fair offers a platform to showcase the latest products and services from the tobacco industry, provided by companies from Indonesia, Asia, and Australia. The fair attracts over 250 international suppliers and serves as a hub where thousands of professionals from the global market come together to network and conduct business.

The main themes of the fair cover a broad spectrum of the tobacco industry, ranging from cigarettes, cigarette tips, cigars, flavor and aroma substances, to water pipes, inspection, testing, and laboratory equipment. Additionally, processing and packaging machines as well as tobacco machinery and wholesale distribution are presented. This highlights the importance of the fair for Dubai and the United Arab Emirates as a trade center and hub of international commerce.

A highlight of WT Middle East are the accompanying conferences, which illuminate current challenges and opportunities in the industry during the two-day event. These conferences are free of charge for all industry employees.

The fair attracts a wide range of visitors, including agencies, manufacturers, equipment purchasers, dealers, and distributors, and with its global focus, is an important event for professionals from various industries.

Furthermore, WT Middle East is part of a series of fairs held worldwide dedicated to the global tobacco industry, emphasizing its role as a significant international platform.

The Dubai World Trade Center as the venue is easily accessible and offers state-of-the-art facilities, providing an optimal framework for this important fair.

In conclusion, the WT Middle East at the Dubai World Trade Center is not only a central event for the global tobacco industry but also reflects the dynamic and innovative business environment of Dubai. As a meeting place for professionals from all over the world to discuss the latest trends, initiate business, and exchange knowledge, the fair plays a key role in promoting international trade and economic development in the region.

Sparkless Knife for cigarette production

In the process of cigarette production, cut-off knife need to work in conjunction with small grinding wheels. They maintain sharpness through continuous grinding to ensure a stable cutting effect. However, the constant friction between the blade and the grinding wheel generates a large number of sparks, which poses a great hidden danger to the production safety of tobacco enterprises and has thus become a core issue repeatedly reported by enterprises.

To overcome this problem and provide customers with more competitive products, our company has invested a lot of energy in researching and developing new materials. After repeated tests and optimizations, we finally successfully developed a special sparkless material. The cut-off knife made of this material can completely avoid spark generation when in instant contact with the grinding wheel, fundamentally reducing the risk of production accidents.

At present, this sparkless knife has been widely adopted by major tobacco production enterprises. It is worth mentioning that its price is basically the same as that of traditional products. While eliminating potential safety hazards, it does not increase the production cost of enterprises, thus winning widespread recognition and a large number of purchase orders in the industry.

In addition, our company has never stopped its research and development efforts. In the future, we will continue to explore more advanced material technologies, striving to launch a new generation of products that can fully replace the existing steel cigarette cutters, truly achieving the ultimate goal of "zero sparks" during the cutting process and contributing more to the safe production of the tobacco industry.

Cigarette testing instrument

In October 2023, Chengdu Libre technology LTD reached a cooperation agreement with Chengdu Retool to sell all testing

equipment owned by Retool overseas.

Retool main products include all kinds of physical parameter testing instruments for cigarettes/filter rods, online automatic

sampling and testing systems for cigarettes/filter rods, testing instruments for various raw and auxiliary materials, and testing

instruments and automation equipment for new materials such as cigarette capsule products. They all have a high market

share in China

The company strictly implements IS09001, IS014001, IS045001, and other standards. All products are designed according to

national and industrial standards and specifications. All key components and parts products are from international famous

brands. The comprehensive quality of products has reached the international level. Product quality, installation and

commissioning, personnel training, after-sales service are guaranteed users.

Libre Attend WT Asia 2024

World Tobacco Asia was held at the Grand City Convex Convention Hall in Surabaya on 09~10 October, 2024. It attracts experts worldwide who are active in tobacco processing and manufacturing of tobacco products. We LIBRE SCIENCE AND TECHNOLOGY CO.,LTD attended the exhibition.

Exhibitors from various sectors, including manufacturers of cigarettes and cigars, suppliers of packaging materials, and developers of inspection and laboratory equipment, use WT Asia as a platform to present their latest products and services to an international audience.

Exhibitors like BMJ, Cerulean, Comas, Focke & Co, G.D, Molins, Sasib, UCM, UTM, US Tobacco Cooperative, etc.

The primary visitors are professionals from the manufacturing industry interested in new suppliers, technologies, and business partners.

Below are a clips from the exbihition:

Libre Science and Technology Supplies Cigar Cutting Circular Blades to The World's Arising Star of Cigar Production

Libre has been supplying tungsten carbide circular blades to cigar industries in the world. And in the first quarter of 2022, Libre successfully made contact with a few cigar manufacturers in central America, taking about long-term cooperation on long-lasting carbide blades.

"Premium hand-rolled cigars are often associated with Caribbean origins, but Nicara-gua and Honduras certainly are changing that notion fast." according to Asia Tobacco Magazine.

Ask consumers in Asia about their favorite high-end, hand-rolled cigar origins and chances are quite high that Cuba and the Dominican Republic are mentioned right off the cuff. The situation is quite different in Europe and especially the United States, the latter being the world’s most important and largest premium cigar market. There, an amazing shift has occurred in recent years. While Cuban and Dominican Republic

cigars firmly retain high rankings on the desirability scale, an astonishing two thirds of all US imports are now comprised of Nicaraguan products. But then again, even some Asian countries such as China, Malaysia, and even Vietnam now show growing inter-est in Central American cigars in recent years. Things are definitely on the right track.

Libre's managing team has high expectations about the potentials of the central Amercia market and is looking forward to offering its technically mature cigar cutting circular blade to this hopeful land, lending a hand to the arising star of centra America premium cigar manufacturers.

Available sizes: 140x46x0.8mm 140x46x0.5mm, be it single bevel or double bevel

Circular knife for Hauni Straw Maker

Paper straw cutting circular knives are used on paper straw production machinery. Regulations restricting single-use plastics have been issued by many countries. With the booming of biodegradable paper drink straws, the need for paper straw making machine and paper straw cutting blades are increasing rapidly. In close cooperation with paper straw machinery manufacturers and paper straw production factories, we better understand the particular characteristics paper straw cutting blades should have, and keep in stock the most commonly used sizes.

Hauni Straw Maker-The world's fastest paper straw maker

The HSM (Hauni Straw Maker) produces visually appealing paper straws at a hitherto unparalleled speed of up to 300 m/min. Its high level of automation ensures above-average quality and an efficiency of more than 90 percent (OEE). At a speed of 300 m per minute, this means you can produce up to 1.8 million straws @ 200mm length during three-shift operation.

Lowest production cost per straw

Paper and glue consumption have been optimized by up to 50% thanks to the linear two-layer production process. Automatic paper feed as well as other innovative automation standards also mean that the machine only requires one operator. One person can even operate two lines.

Technology proven worldwide

For five years now, 30 machines similar to the HSM have been used by the international tobacco industry to produce special filters. The technology, already established in the marketplace and tested under real conditions, has now been adapted to produce high-quality paper straws, thereby offering an expertise-based, robust solution for the future.

Technical Benefits (Maker)

Up to 300 meters/minute for fastest paper straw making

Up to 90% of efficiency

Up to 50% less glue

No need of additional slip additives (vegetable oils, etc.) and no additional heat treatment to cure the glue

High level of automatization: less man power needed

Automatic splice detection & rejection

1 type of paper needed: online cutting to get 2 layers

Diameter/ length change in 8h/1h

24/7 service worldwide

Industrial Cutting Blades With Coating

The coating tool is prepared by coating a thin layer of refractory metal or nonmetal compound with good wear resistance (also can be coated on ultra-hard material blades such as ceramic, diamond and cubic boron nitride) on the surface of tungsten carbide or high speed steel (HSS) substrate with good strength and toughness by vapor deposition method. The coating acts as a chemical and thermal barrier, reducing the diffusion and chemical reaction between the tool and the workpiece, thereby reducing the wear of the matrix. Coating tool has high surface hardness, good wear resistance, stable chemical properties, heat resistance and oxidation resistance, small friction coefficient and low thermal conductivity characteristics, cutting than uncoated tool life increased 3~5 times more than, improve the cutting speed of 20%~70%, improve processing accuracy 0.5~1 level, reduce tool consumption cost 20%~50%.

current situation

Coated cutting tools have become the symbol of modern cutting tools, in the tool used in more than 50%. Various cutting tools used in machining, including turning tool, boring tool, drill, reamer, broach, tap, thread comb, rolling head, milling cutter, forming tool, gear hob and gear shaper, etc., can be coated to improve their performance.

coating material

The coating material must have high hardness, good wear resistance, stable chemical properties, no chemical reaction with the workpiece material, heat resistance and oxidation resistance, low friction coefficient, and solid adhesion with the matrix and other requirements. Obviously, a single coating material is difficult to meet the above requirements. Therefore, the hard coating materials have been only coated with a single TiC, TiN, Al2O3 at first, into the development of thick film, composite and multiple coatings in a new stage. The newly developed TiCN, TiAlN, TiAlN multilayer, ultra-thin, ultra-multilayer coatings are combined with TiC, TiN, Al2O3 and other coatings, and the new anti-plastic deformation matrix has made great progress in improving the toughness of coatings, the bonding strength between coatings and substrates, and improving the wear resistance of coatings. The technology of coating diamond film on carbide matrix has been broken through and the performance of cutting tool has been improved comprehensively.

TiN is the most mature and widely used hard coating material, but the bonding strength between TiN and the matrix is not as good as TiC coating, the coating is easy to peel off, and the hardness is not as high as TiC, and the film is easy to be oxidized and ablated when the cutting temperature is higher. TiC coating has high hardness and wear resistance, oxidation resistance, but its brittle, impact resistance. TiCN has the advantages of TiC and TiN. It can control TiCN properties by continuously changing the composition of C and N during the coating process, and form a multi-layer structure of different components, which can reduce the internal stress of the coating, improve the toughness, increase the thickness of the coating, prevent the expansion of cracks, and reduce the edge breaking. TiCN based coating is suitable for processing ordinary steel, alloy steel, stainless steel and wear-resistant cast iron, and the material removal rate can be increased by 2~3 times.

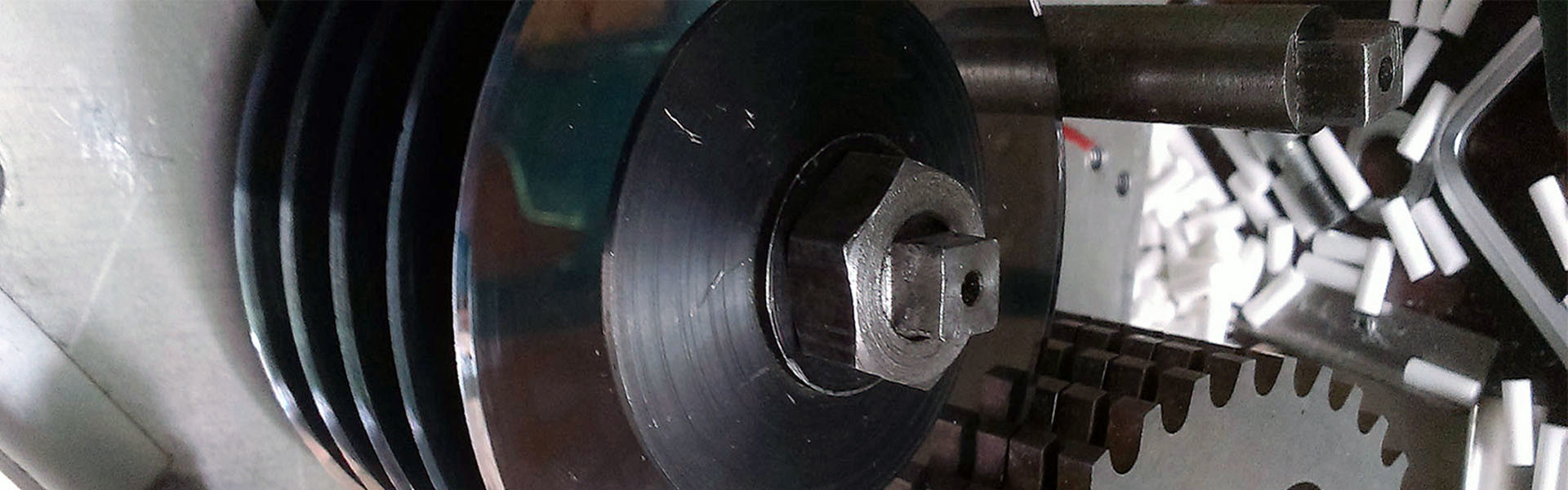

Hauni Protos New Design Performance-Improved Suction Drum

Performance-Improved Series Protos making lines

Tipping drum with cutting knife separated from suction plates, knives being separated from suction plates prolongs the working life to 4 times longer!

For most suction drums (with cutting knives) in the market, the knives are combined with suction plates. In the production process, you need dismantle the whole out smoothly. The drum need to be repaired or just throw away. Normally, the working life of this kind of drum is just around 4500 hours.

Tipping drum with cutting knives separated from suction plates adopted a new design. As showed in the picture, the cutting knives are not combined with suction plates anymore, they are separated and working side by side. (the cutting knives now are reversible and have four cutting edges) The changed design makes the suction plate work under a sole purpose (absorb the tipping paper), and be no longer easy to break. The reversible cutting knife could be used as four brand new knives by turning one side up after another when the working side gets blunt or breaks. So reversible cutting knife has a working life four times longer (as long as appx. 18,000 hours) than the normal one-edge knife, and also owns a more precise and reasonable cutting angle. And as a result, the spare part cost is reduced and the mentainance period is extended.

Easy to Mentain and Stable in Performance

For the new kind of drum, you do not have to tear apart the whole drum when you need replace the blunt knives, and you just need turn up another side of the cutting edge and then relocate the knife on the drum. It helps shorten the stop-time. How good you mount the knife onto the drum is decided by the precision of the drum and the knife, and you do not have to adjust with extremely special care or use any special tool to finish.

On the new drum, the suction plate is made of composite ceramic matererial, which largely reduces the weight of the drum, effectively lightens the load on the gear and prolong the working life of it, thus the gear can work precisely.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!