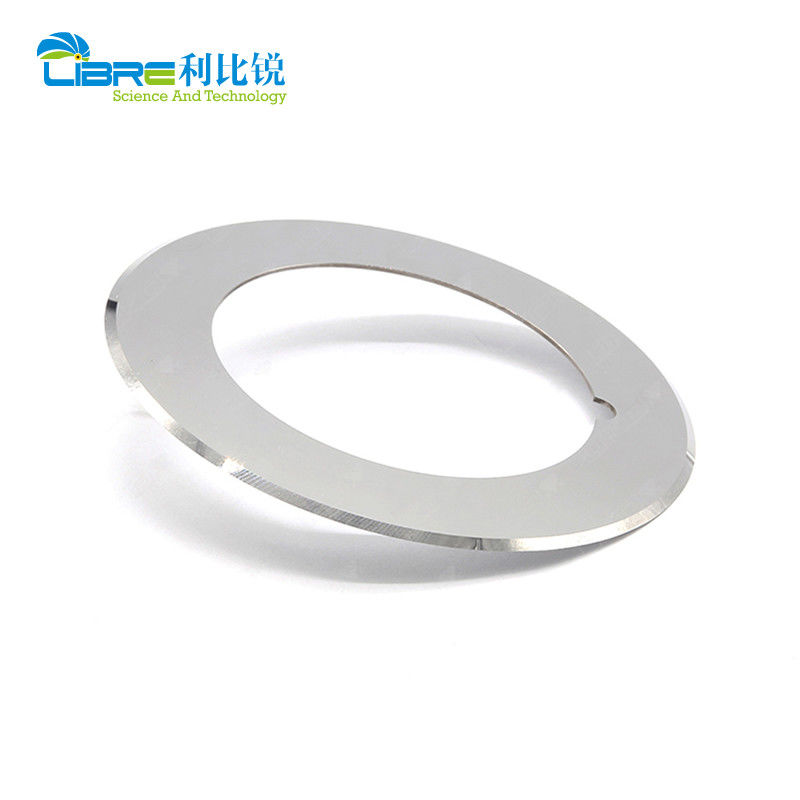

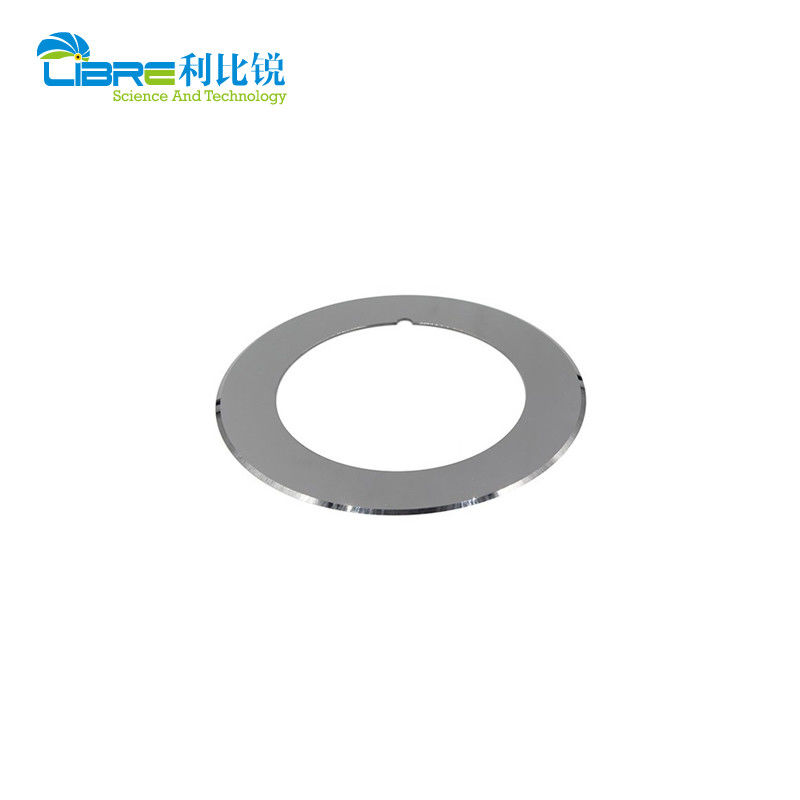

Lithium Battery Cutting Top Slitting Blade

Our factory offering world-class performance, which is the leading global supplier of lithium battery cutting blades.

For more than 20 years, Libre has provided smart energy solutions and service excellence for the European market.

This lithium cell slitting blade is used in lithium batteries pole piece cut. According to the cutting material, generally

80,000 meters to 300,000 meters.

Apply to: Nishimura, Yakang, Lange, Win Together, Ho Van, Seven Star Chinese Creators.

Cutting Material: Lithium iron phosphate, lithium manganse oxide, cobalt oxide, ternary and so on.

Material: Ultrafine tungsten carbide powder

Working life: According to the cutting material, generally 80,000 meters to 300,000 meters.

Use: This product is used in lithium batteries pole piece cut.

Application Field: Automotive, Marine, Aerospace, Grid-Storage, Oil gas etc.

Characteristic of Circular Slitter Blades:

1.Material

The lithium battery circular slitter blades are made of 100% tungsten carbide material

2.Hardness guarantee

The raw materials are heat treated, vacuum treated, and the hardness is higher. Heat treatment in your own factory to ensure product stability.

3.Sharp edge

The knife edge is sharp, smooth, sharp and durable, imported precision processing equipment can process a variety of non-standard products to ensure the precision of the products.

4.Long service life

Low friction coefficient and long service life, each blade detects inbound shipments, ensuring quality without worry.

Lithium Battery Cutting Blade Display:

Application of Circular Slitter Blades:

These blades are used for lithium battery pole piece cutting. The ultrafine particles of tungsten carbide sitting lithium iron phosphate, lithium manganese oxide, cobalt oxide, and other materials. Nishimura, Yakang. Lange, supporting, Hao can win, qixinghuachuang Supporting the sharp maxima, Dudley, models life can be divided according to the material, usually in the 80 thousand meters to 300 thousand meters range.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!