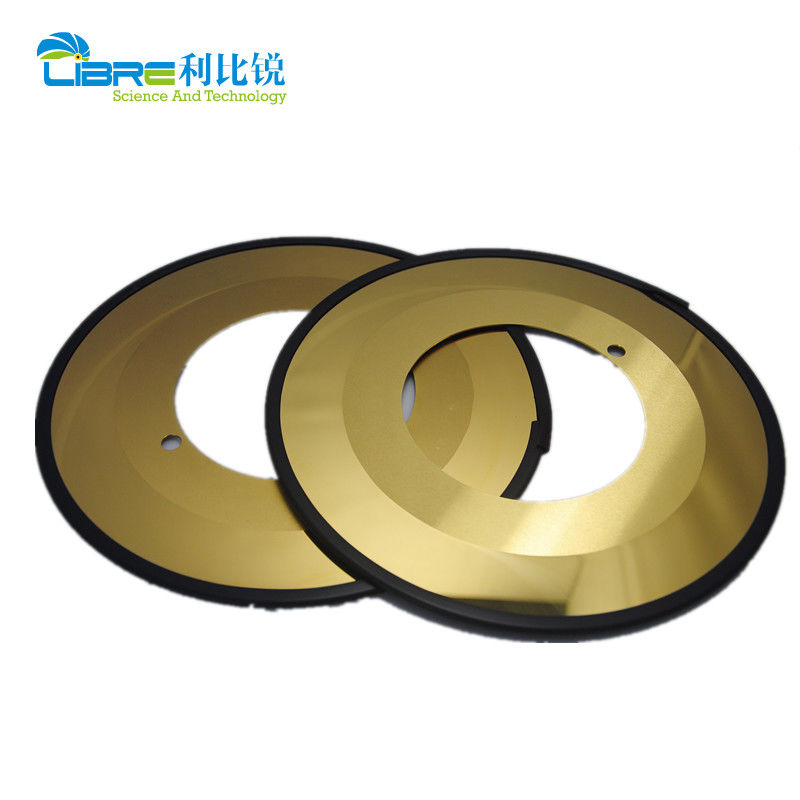

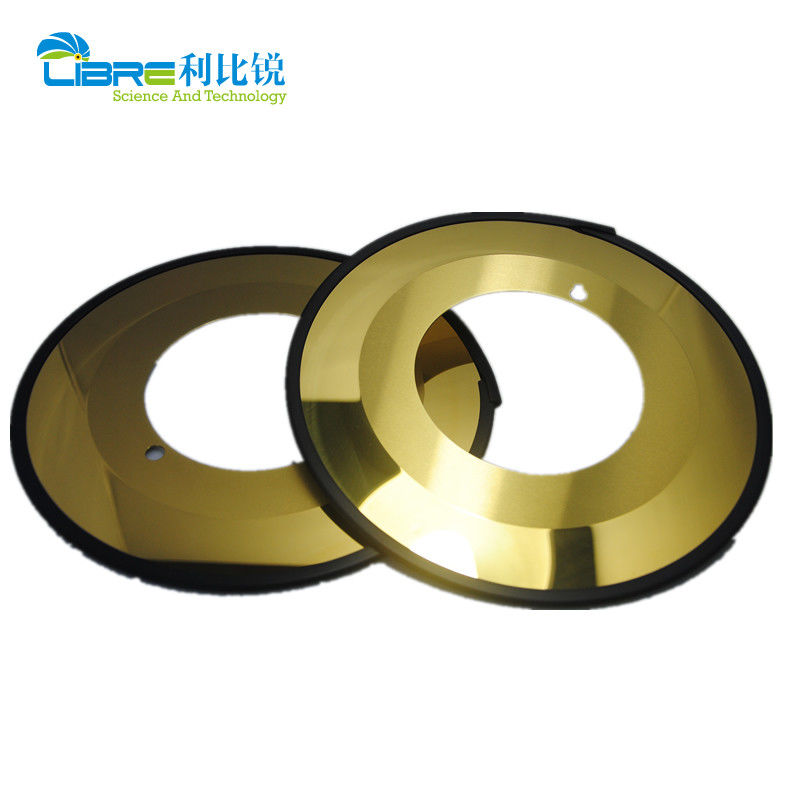

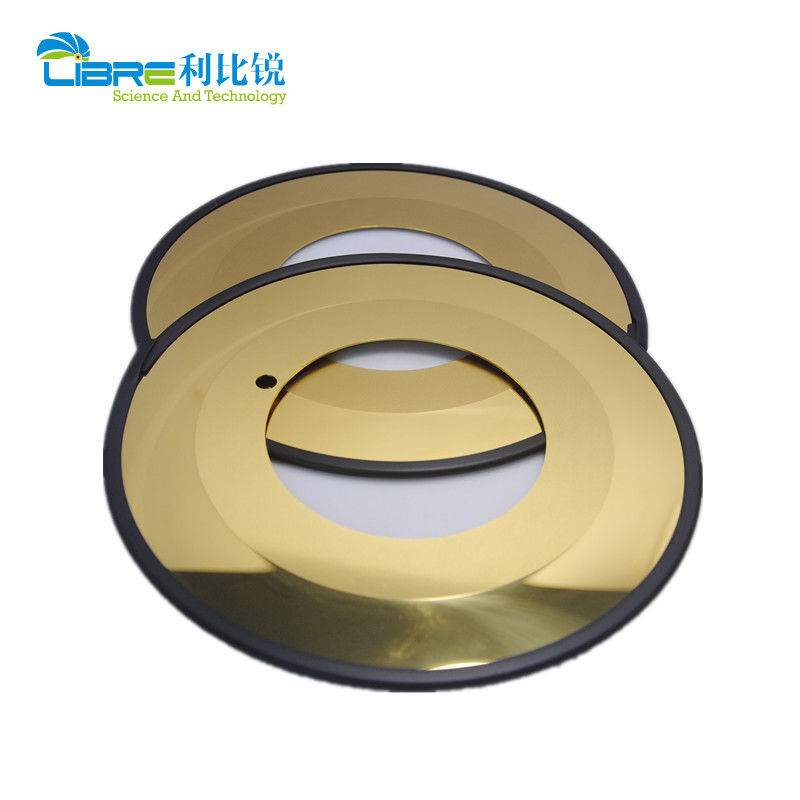

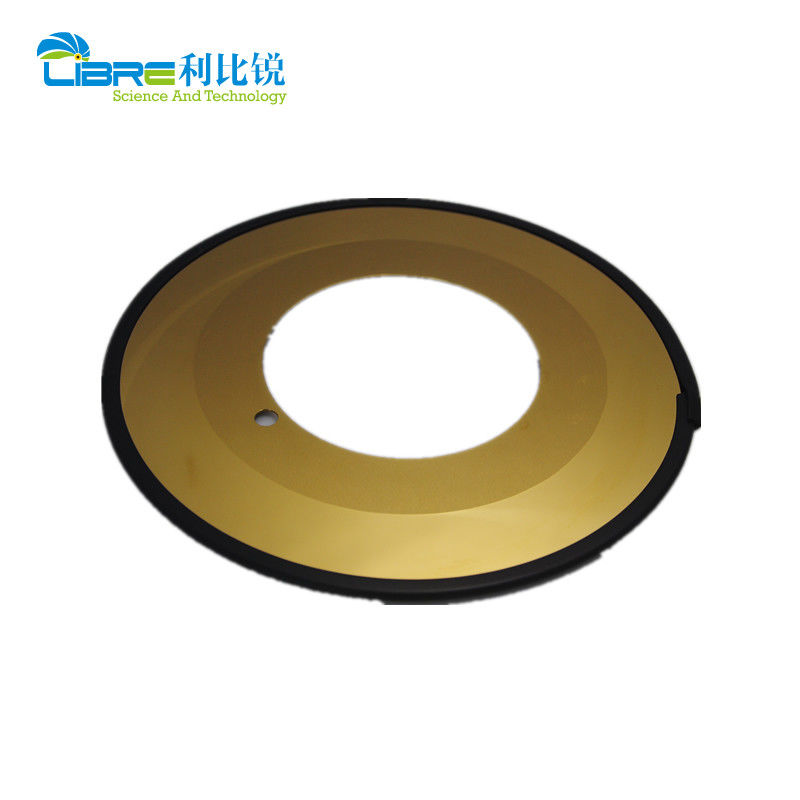

Titanium Plating Tungsten Carbide Razor Slitters for Agnati Scorer

This tungsten carbide razor slitters is different from normal Agnati blades, which has only one hole. The normal

one we can see is with three holes. And surface is titanium plating which can greatly improve abrasive resistace.

In this way, it can extend its lifetime, reduce the number of blade replacements.

Features and advantages

Our high tech tungsten carbide razor blades are used successfully in many corrugated cardboard production

plants worldwide. Selecting the optimum composition of tungsten and cobalt with optimal grain size, our

razor blades achieve longer life time in terms of additional million meters of corrugated cardboard cutting

in comparison to the average duration of blades made in Europe.

The cutting surfaces of razor blades are mirror polished to reduce the work friction, extending the lifetime

of the blade and reducing the noise level during cutting.

- Higher quality level.

- Competitive prices level.

- Maximum blade lifetime is 16 million meters.

- Higher mirror finish (Ra = 0,02 µm).

- Each blade is separately packed.

Tungsten Carbide Razor Slitters Common Sizes:

| Model |

OD |

ID |

Thickness |

Number of holes |

Hole dia |

| Agnati |

220 |

115 |

1.0 |

3 |

9.0 |

| Agnati |

240 |

115 |

1.0 |

3 |

9.0 |

| Agnati |

240 |

115 |

2.0 |

3 |

9.0 |

| BHS |

240 |

32 |

1.2 |

2 |

8.5 |

| Fosber |

230 |

110 |

1.1 |

6 |

9.0 |

| Fosber |

230 |

135 |

1.1 |

6 |

9.0 |

| Fosber |

291 |

203 |

1.1 |

6 |

8.5 |

| Isowa |

260 |

140 |

1.1 |

6 |

9.5 |

| Marquip |

260 |

168.3 |

1.2/1.3 |

8 |

10.5 |

| Mitsubishi |

280 |

202 |

1.4 |

6 |

7.6 |

| Mitsubishi |

280 |

160 |

1.1 |

6 |

7.6 |

| Peters |

250 |

150 |

0.8 |

|

|

| Peters |

250 |

150 |

1.2 |

|

|

| TCY |

300 |

112 |

1.2-1.5 |

6 |

12.0 |

| Justu |

200 |

122 |

1.2/1.3 |

|

|

| Kaituo |

230 |

110 |

1.3/1.4 |

|

|

| Justo |

260 |

158 |

1.4/1.5 |

8 |

11.0 |

| Oranda |

265 |

112 |

1.4 |

|

|

Tungsten Carbide Razor Slitters Display:

Company information

Libre is one of the first companies which started development and production of wear-resistant materials. It involves in the research and development of tungsten carbide material, the production of carbide industrial knives and blades and tobacco machinery spare parts.

Libre has over 20 years' experience of making carbide industrial knvies, specializied in slitting blades. Half of our products are for exportation. We have the ability to cater to requests from customers of different countries. Our "Libre" brand industrial knives take a leading position in both domestic and overseas markets where slitting is required.

Based in China and located in Chengdu City, we become a factory specialized in carbide slitting blades of comprehensive product category, striving to provide global customers more convenient, faster, stabler services and quality products.

We keep oursevles at the world-class level by bringing in advanced CNC center and quality checking equipments, hiring high-tech talents to ensure the product quality. We not only develop Chinese market, but also want to have a share of the global market, and provide better and abundant spares and services.

Our Advantages

20 years experience

1). Size standard or as per your requirements;

2). Very advantageous price.

3). Good English communication;

4). Professional technology on product;

5). Could accept trial order.

Quality guarantee

1). High-quality raw materials and years of processing and production experience ensure stable product quality;

2). Strict inspection process to ensure that each product is qualified.

24-hour service

1). 7×24 hours online service, tracking the progress of the order at any time, and timely feedback to the customer.

2). Provide other services to customers

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!