We supply physical characteristics testing instruments for tobacco industry. For example, the measuring and testing equipments for the bellow areas.

1. regular cigarette/filter rods

2. capsule cigarette/filter rods

3. heat-not-burn cigarettes

4. cigars

5. flavor capsules

We also can cater to your specific testing requirements and customized the tobacco insepction stations.

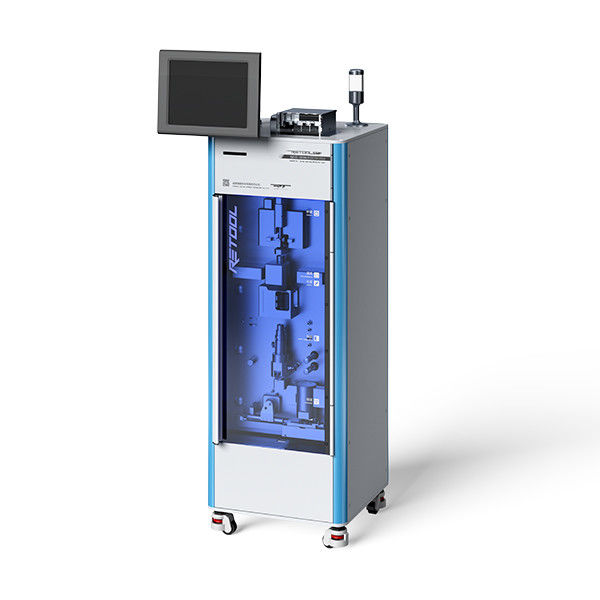

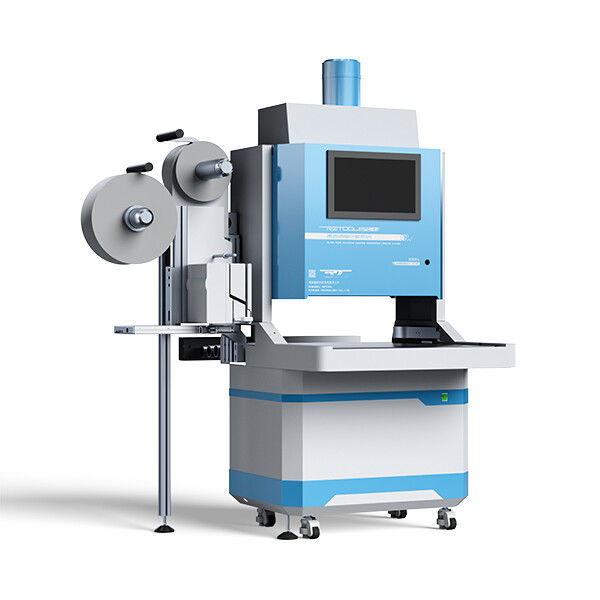

RT Cigarette Filter Rod Multifunction Test is a comprehensive test bench product used to measure the physical parameters of cigarette and filter rod, such as weight, circumference (roundness), length, draw resistance, ventilation rate and hardness. The test bench adopts a combined modular design, with high degree of automation. Each test unit performs independent and synchronous automatic measurement, and is compatible with samples of various specifications, including regular cigarettes, medium cigarettes, thin cigarettes, special cigarettes, heat-not-burn cigarettes, common filter rods, medium filter rods, thin filter rods and special filter rods. It can be combined into comprehensive test bench products of different measurement items according to the actual needs of users.

RT Cigarette Filter Rod Multifunction Test applies to many links in the cigarette and filter rod production, such as on-line sampling inspection in the production workshop, and inspection and spot check of cigarette and filter rod samples in testing stations and laboratories at all levels. The test bench uses a Chinese (English or other languages optional) operation interface, easy to operate and learn.

Performance and Features

1. General features: Test the physical parameters of cigarettes and filter rods, including weight, circumference, roundness, length, cigarette draw resistance (open type, closed type), filter rod pressure drop, ventilation rate, hardness, etc.

2. Modular design, drawer-type structure: Combine different units as needed, and also close or open the specified test items.

3. Panel type unit layout: Beautiful and elegant, easy to observe the measurement process, troubleshooting, etc.

4. Feeding device: Adopt an automatic roller-type hopper, which can be switched automatically to the coarse, medium and fine levels according to the sample grade.

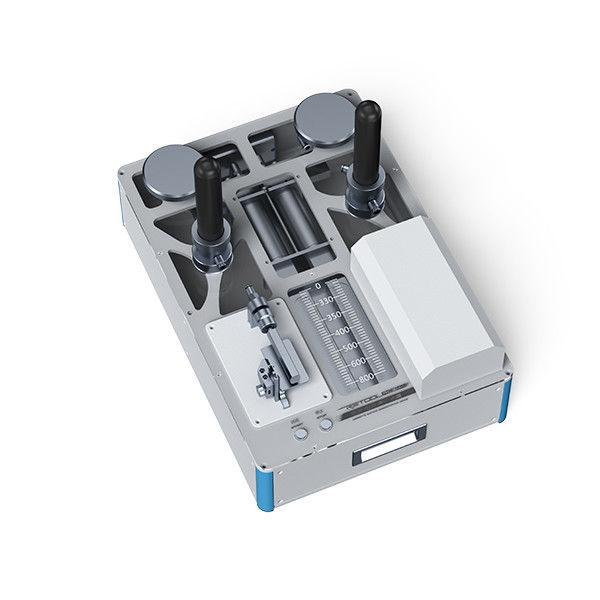

5. Weighing unit: Adopt an imported high-precision balance (with anti-electromagnetic interference function), built-in automatic calibration function, and automatic peeling during measurement (to avoid dust and other debris), and equipped with electronic level, convenient to adjust the balance levelness.

6. Circumference unit: Adopt a holding device, and a stepless adjustment device for the height of base surface. Users can customize the measurement position according to actual needs, and test the transparent filter rods.

7. Length unit: Adopt a holding device and a height reference positioning device. It is not necessary to repeat calibration when switching the grade.

8. Draw resistance unit: Adopt advanced technologies such as valve block, wedge seal, temperature and humidity monitoring, built-in standard rod automatic calibration, anti-static, etc. Pressure drop of test line <10Pa.

9. Hardness unit (air bearing): Adopt advanced technologies such as applying the vertical pressure with weights, air bearing zero friction, laser non-contact measurement, etc. The sample is automatically centered, and the measurement position is adjusted with the stepless adjustment device. The user can customize the measurement position according to the actual demand.

10. Control system: The control computer is a 15-inch industrial tablet computer with Chinese operating system.

11. Data output: Adopt thermal printer, network interface, USB interface, with data acquisition and upload capabilities.

12. Provide external alarm lights with light warning function.

13. Power supply and air source: Adopt the industrial power supply with high anti-interference capability; Equipped with oil-water separator and micro-mist filter to strengthen gas source purification.

14. Service and maintenance: Built-in remote diagnosis and maintenance function.

Technical parameters

| Hopper capacity |

70 pcs (at 7.8mm diameter) |

| Operating speed |

Up to 6 pcs/min |

| Sample collection |

Unordered collection, more than 200 pieces |

| Critical flow orifice (CFO) |

17.5±0.1ml/s (made of imported precious stones) |

| Distance between hardness test point and sample end face |

0-75mm |

| Distance between circumference test point and sample end face |

47-119mm |

| Overall size |

600x600x1400mm (low case) |

| |

600x600x1600mm (high case) |

| |

Excluding alarm lights and computers |

Conventional measurement indicators:

| Item |

Measurement range |

Resolution |

Precision |

| Weight |

0~ 200.000g |

0.001g |

±0.001g |

| Circumference |

15.5 ~ 28.5mm |

0.001mm |

±0.002mm |

| Length |

55 ~ 150mm |

0.005mm |

±0.01mm |

| Draw resistance |

0~10KPa |

1Pa |

±0.5%FS |

| Ventilation rate |

0-100% |

0.1% |

±1.0%FS |

| Hardness |

Pre-pressure |

10g (adjustable) |

0.1g |

±1g |

| |

Pressure |

300g (GB) |

0.1g |

±1g |

| |

Time |

15.0s (adjustable) |

0.1s |

±0.1s |

| |

Displacement |

0~ 10mm |

0.005mm |

±0.01 mm |

| |

Hardness |

0-100% |

0.1% |

±0.1% |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!